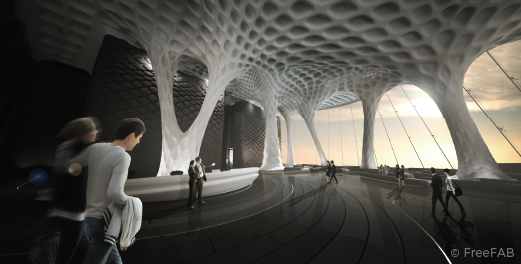

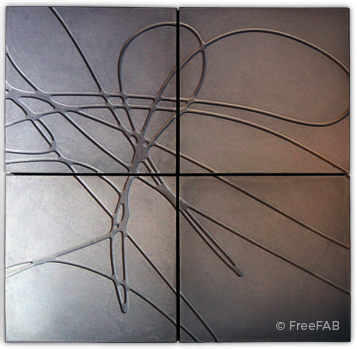

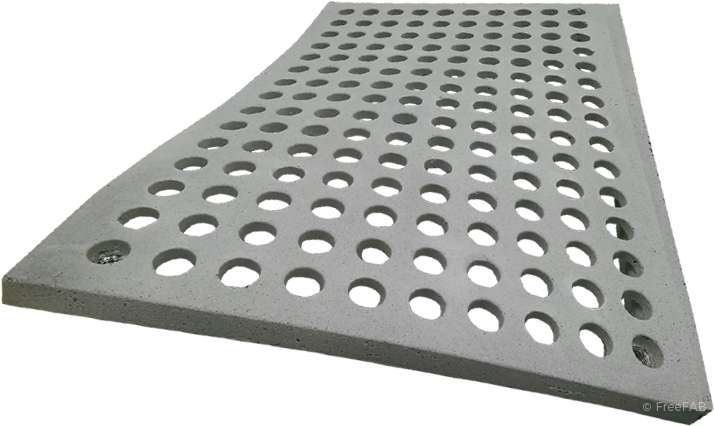

FreeFAB™ Wax is a construction scale 3D printing technology that allows complex concrete building components and prototypes to be designed & developed more cost effectively and with shorter lead times than current alternatives.

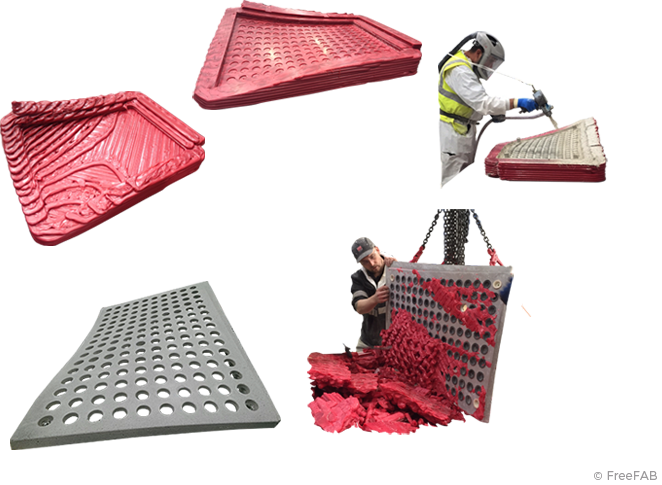

The FreeFAB™ Wax technology combines both 3D printing and 5 axis surface milling to deliver a hybrid technology for the fabrication of precision moulds for the construction and other industries.

The FreeFAB™ Wax is ideally suited to off-site precast factory environments, producing moulds for simple to complex precast and GRC products more efficiently than conventional technologies.

Sustainability

FreeFAB™ Wax offers significant benefits over conventional mould production, as the wax from moulds is filtered and re-used directly, recovering more than 90% of materials. This result in dramatically less waste, lower embodied energy in each product and reduced material consumption. This benefit supports the sustainability agenda of Laing O'Rourke & FreeFab, and reduces the carbon footprint of both production and products.

Contact

Engineering Excellence GroupLaing O'Rourke

L2/97 Rose Street,

Chippendale, NSW Australia